Exploring Rockwell Hardness Testing: Method, Process, and Practical Importance

In materials science and engineering, rockwell hardness testing is one of the most popular and reliable methods of testing the hardness of metals and alloys. It helps to establish how resistant a material is to deformation under applied load -- a property which plays an important role in determining the quality, performance, and durability of products. Because of its simplicity, accuracy and speed, this method has become a laboratory, production line and research facility standard all around the world.

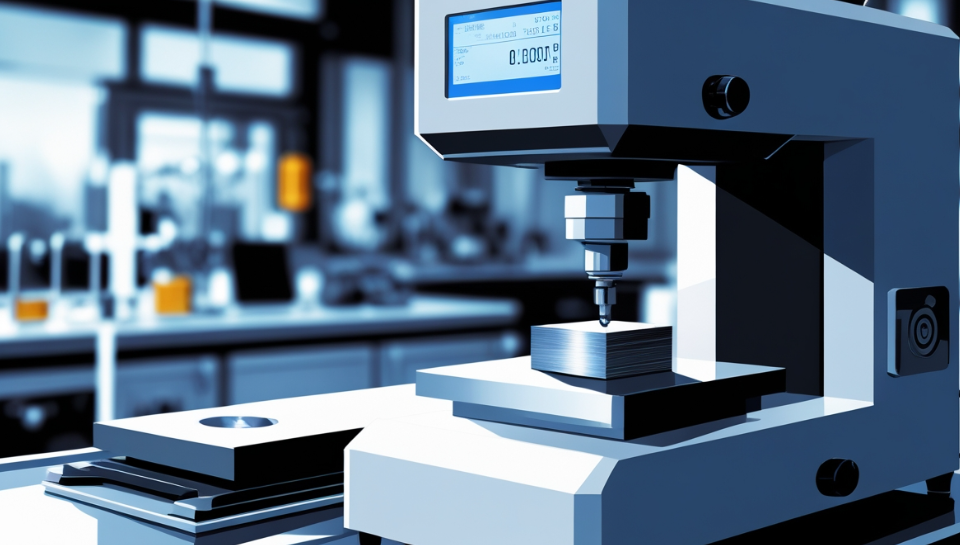

What Is the Rockwell Hardness Test?

Rockwell hardness testing is a type of depth-based hardness measurement method which measures the depth of penetration of an indenter into the material under a specified load. Unlike other hardness tests, such as Brinell or Vickers, where the diameter or diagonal of an indentation is measured, with Rockwell testing the depth of the indentation is directly measured and the result is much faster and more precise.The test has two main stages -- application of a minor load and then a major load. The minor load is used to set a zero reference point by pushing the indenter slightly into the surface. Then, a major load is applied for a certain dwell time in order to create the main indentation. Once the higher load has been removed, with the difference in the depth of the minor and the major loads automatically measured. The less depth of the indentation, the higher hardness value of the material.

The Rockwell Testing Procedure

Although it seems to be a straightforward procedure, rockwell hardness testing involves a standardized sequence of steps in order to deliver accuracy and consistency:

Sample Preparation

The surface of the specimen must be clean, clean, smooth and free from scale or coatings. Any roughness can have an effect on the accuracy of depth readings. Polishing or light grinding is usually recommended.

Applying the Minor Load

The test starts from a small load (usually 10 kgf) that sets a reference position and adjusts for irregularities on the surface.

Applying the Major Load

A major load is then applied, depending on which Rockwell scale is being used. The combination of loads and indenter type depends on material hardness and material thickness.

Dwell Time and Unloading

The load is held for a defined dwell time, thereby leaving a time for the material to stabilise. The major load is then released and only the minor load is now applied.

Measurement and Calculations

The machine automatically measures the depth of the indentation and displays the hardness value directly in terms of Rockwell number (HR) of a hardness value and a particular scale (e.g., HRA, HRB, HRC).

Repeat Testing

Multiple indentations are typically made in the specimen at different locations. The average reading provides a more reliable value of hardness as well as reveals the structural variations.

Scales of Rockwell and Their Applications

Different Rockwell scales are used to test different ranges of hardness of materials. The HRC scale uses a diamond cone indenter and is used for hardened steels, whereas HRB uses a steel ball for softer materials such as copper and brass. HRA is used for very hard materials such as tungsten carbide. Superficial Rockwell scales (e.g. HR15N, HR30T) are intended for thin coatings or delicate materials where heavy loads can cause damage.The wide range of scales makes rockwell hardness testing suitable for use in automotive, aerospace, manufacturing, and research industries. It is often used to check the results of heat treatment, assess surface hardening, and ensure that parts meet material specifications before they are assembled or shipped.

Advantages of Rockwell Hardness Testing

Several features make Rockwell testing one of the most popular methods of hardness testing:Quick and Direct Results: Hardness numbers are displayed quickly without optical measurement.Repeatable and Reliable: Depth-based readings reduce human error.Versatile: Multiple scales provide test capability for testing soft and hard materials.Minimal Preparation Required Only a smooth flat surface is necessary for accurate results.Automatable: Modern machines have the ability to record, store, and analyze data efficiently.Due to these advantages, Rockwell testing is seen as a go-to method of production quality control and routine inspection tasks.

Factors That Affect Accuracy

To get the precise results, few critical conditions must be controlled during the rockwell hardness testing. The test surface should be properly prepared and the specimen should be of adequate thickness to prevent deformation under the test area. Indentations should be spaced apart and away from edges sufficiently. Regular calibration with certified reference blocks is necessary to keep the tester reliable. Environmental factors such as vibration and temperature changes may also affect readings and should be minimized.

Conclusion

Rockwell hardness testing is a basic tool in contemporary materials testing. By measuring the depth of an indentation under controlled loads, it has given a fast, objective and repeatable measure of the mechanical strength of a material. Its ease of use and adaptability make it ideal for everyday laboratory testing, industrial inspection and research analysis. Whether testing the hardness of metals after heat treatment or ensuring the consistency of production, Rockwell testing remains an important part of ensuring the reliability and performance of engineered materials in various industries.