Save Money While Perfecting Your Prototype With These Tips

Prototype development can drain your budget faster than you expect. Smart entrepreneurs know that cutting costs during the prototyping phase doesn’t necessarily mean compromising quality—it means working strategically. The key lies in making informed decisions about materials, processes, and timing that preserve your vision while protecting your bottom line.

Choose Your Materials Strategically

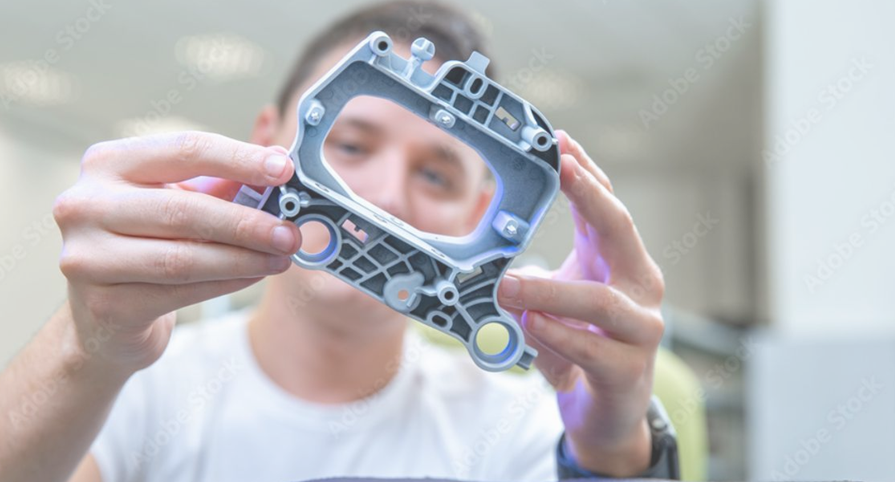

Material selection dramatically impacts both prototype performance and production costs. Start with affordable alternatives that mimic your target material’s properties. For instance, if your final product requires aluminum, consider using high-density foam or composite materials for initial testing. Using the best high-quality 3D printing materials for specific prototype phases can reduce overall costs. Premium materials might cost more upfront, but they often eliminate the need for multiple iterations and repairs. Consider the prototype’s intended use before selecting materials, and match your material investment to your testing goals. Functional testing requires different material properties than aesthetic evaluation.

Optimize Your Design for Cost-Effective Production

Design complexity directly correlates with production expenses. Simplify geometries where possible without compromising core functionality by removing unnecessary features that add manufacturing steps or require specialized tooling. Standardize components across your prototype whenever feasible. Using common fasteners, standard dimensions, and readily available parts reduces both material costs and assembly time. This approach also streamlines future manufacturing processes.

Leverage Technology and Service Partnerships

Modern rapid prototyping solutions offer unprecedented flexibility in balancing cost and capability. Compare different manufacturing technologies for each prototype iteration. Some features work better with additive manufacturing, while others benefit from traditional machining or casting. Partner with prototyping services that offer volume discounts or package deals. Many providers reduce per-unit costs when you commit to multiple iterations or combine different manufacturing processes in a single order.

Time Your Iterations Strategically

Rushed prototypes often cost more and perform worse than those developed with proper planning. Create a realistic timeline that allows for proper testing between iterations. Quick fixes usually require expensive rush orders or premium shipping. Plan your testing phases to maximize learning from each prototype. Comprehensive testing reduces the need for additional iterations and helps you identify cost-saving opportunities for future versions.

Start Building Smarter Prototypes Today

Effective prototype development requires discipline and strategic thinking. Focus your spending on areas that directly impact your product’s core value proposition. Every dollar saved during prototyping can fund additional market research, user testing, or manufacturing preparation. Remember that the cheapest prototype isn’t always the most cost-effective. Invest in quality where it matters most for your specific application, and save money on elements that don’t affect your testing objectives.