Optimizing Industrial Equipment Performance with Predictive Maintenance

Key Takeaways

- Predictive maintenance uses advanced data analytics to anticipate equipment failures and reduce costly, unexpected downtime.

- Companies benefit from improved operational efficiency, safety, and significant cost savings through proactive equipment management.

- Adoption across various industries has yielded impressive results, with real-world examples showcasing substantial performance improvements.

In today's fast-paced industrial sector, the reliability and efficiency of machinery are non-negotiable factors that drive profitability and safety. To stay ahead, businesses are increasingly turning to predictive maintenance, a proactive approach that leverages advanced analytics to forecast potential equipment breakdowns before they occur. Organizations like C&B Equipment support this transformation, enabling manufacturers to operate smoothly and avoid disruptive failures.

Predictive maintenance minimizes guesswork by utilizing real-time data collected from industrial assets, enabling the planning of repairs based on the actual condition of the equipment rather than fixed schedules. Not only does this approach enhance performance and uptime, but it also transforms maintenance strategies from reactive to proactive, supporting greater productivity and improved cost management.

The industrial landscape is evolving with digital transformation, and staying competitive requires adopting innovative solutions to enhance equipment reliability. Predictive maintenance is at the forefront, helping businesses maximize output and minimize operational risk. By leveraging tools such as sensor technology, artificial intelligence, and cloud-based analytics, companies can shift their maintenance programs from costly emergency repairs to intelligent, data-driven action.

With real-world use cases demonstrating significant gains across diverse industries, predictive maintenance is rapidly becoming essential for manufacturers looking to future-proof their operations. This article examines what predictive maintenance is, its tangible benefits, how to implement it, and the emerging trends that are shaping its future.

Understanding Predictive Maintenance

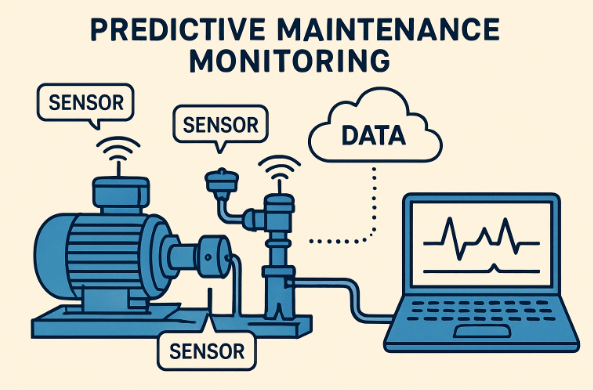

Predictive maintenance is a forward-thinking maintenance strategy that monitors the health and performance of machinery in real time. Sensors continuously collect data on variables like temperature, vibration, pressure, and wear. This data is analyzed to identify early signs of deterioration or irregularity that could signal an impending failure.

Instead of following set maintenance intervals, companies can make informed decisions about when and how to service their equipment, reducing the likelihood of unexpected breakdowns. The approach leverages a combination of Internet of Things (IoT) devices, machine learning, and big data analytics, allowing maintenance teams to focus resources on issues that truly require attention. For a deeper understanding of how IIoT and big data are transforming equipment maintenance, resources such as Forbes Technology Council offer additional insights.

Benefits of Predictive Maintenance

- Reduced Downtime: Predicting failures enables maintenance to be scheduled during planned outages or low-demand periods, ensuring uninterrupted production flow.

- Cost Savings: By preventing catastrophic breakdowns, businesses save money on emergency repairs and extend the operational lifespan of critical assets.

- Improved Safety: Addressing problems before they result in hazardous incidents enhances safety conditions for facility personnel and protects valuable equipment.

Additionally, predictive maintenance minimizes inventory costs by requesting replacement parts only when necessary, thereby reducing excess stock. It also supports environmental goals by encouraging energy efficiency and minimizing waste associated with unplanned maintenance activities.

Implementing Predictive Maintenance

- Data Collection: Begin by installing sensors on critical assets to monitor operating parameters in real-time. These sensors capture crucial data points, including vibration frequency, temperature changes, oil quality, and acoustic emissions.

- Data Analysis: Use dedicated analytics software to process and interpret streams of data. These systems utilize machine learning algorithms to identify patterns and anomalies, alerting when intervention may be necessary.

- Maintenance Scheduling: Maintenance schedules are then created or refined based on predictive insights, allowing repairs to be performed only when required, which can lead to significant efficiency improvements.

Organizational change is often required as well, as teams adopt new processes and training to maximize the value of predictive analytics. Integration with existing enterprise resource planning (ERP) platforms is also essential to streamline workflows.

Real-World Applications

Leading corporations have adopted predictive maintenance to revolutionize their operations. For example, General Electric (GE) utilizes its Predix platform to monitor industrial assets, reporting a 20% reduction in unplanned downtime and a 10% increase in asset utilization. Siemens, another global powerhouse, has experienced a 30% increase in productivity and a 25% reduction in energy consumption after integrating predictive technologies into its processes.

These results underscore how predictive maintenance not only saves money but also supports sustainability initiatives through better resource management and reduced energy use.

Challenges and Considerations

- Initial Investment: Installing new hardware, software, and training specialists requires upfront costs that may be challenging for smaller enterprises.

- Data Management: The sheer volume of data produced requires a robust IT infrastructure, quality control measures, and skilled personnel to accurately interpret analytics.

- Integration: Marrying predictive maintenance systems with existing equipment and operational workflows can be complex, requiring tailored integration strategies and change management.

Despite these hurdles, strategic planning and guided implementation can address these concerns, delivering substantial long-term returns on investment. Thought leadership in this area from sources like McKinsey & Company stresses the importance of aligning predictive maintenance strategies with broader digitalization goals for maximum impact.

Future Trends

The evolution of predictive maintenance is closely tied to advancements in artificial intelligence and machine learning. These technologies are making predictive models more accurate, expanding their potential applications across even more industries. Cloud computing and edge analytics ensure insights are timely and accessible, further streamlining maintenance practices and improving reliability.As more organizations embrace Industry 4.0, predictive maintenance will become the norm rather than the exception. This trend empowers facilities to operate efficiently, reduce waste, and maintain a competitive edge through continuous improvement strategies.Predictive maintenance is a vital strategy for optimizing the performance of industrial equipment. Organizations that proactively adopt these technologies gain a competitive edge in safety, cost control, operational reliability, and sustainable growth.